Australian Pulley Co. breaks down 5 types of Shaft Collars for industrial applications, helping you select the best option in this comprehensive 2025 guide.

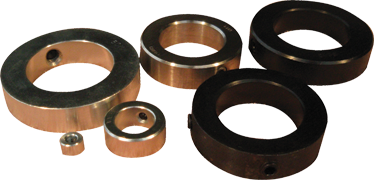

Shaft collars are essential components used in a variety of industrial applications to secure and position shafts, bearings, and other mechanical parts. These simple yet effective devices come in various styles, each tailored for specific uses and environments.

As industries evolve and technology advances, knowing the different types of shaft collars and their applications can help streamline operations and enhance efficiency. This guide will let you compare five types of shaft collars to assist you in selecting the most suitable options for your needs in 2025.

5 Types of Shaft Collars Compared for Industrial Use in 2025

Understanding the specific requirements of your application is key to selecting the right shaft collars. Here are five prominent types to consider:

• Set Screw Shaft Collars: These collars feature a screw that tightens against the shaft, creating a secure fit. Set screw collars are commonly used in applications where precise positioning is essential.

• Clamp Shaft Collars: Known for their superior grip, clamp shaft collars provide a tight hold without marring the shaft’s surface. This makes them ideal for applications where shaft integrity is crucial.

• Flanged Shaft Collars: Flanged collars have a lip that helps to prevent axial movement, which is beneficial in applications requiring additional stability. These collars are widely used in heavy machinery and automotive applications where load bearing is significant.

• Collar Shaft Collars: These are simpler in design and provide a robust solution for many standard applications. Collar shaft collars are versatile and can be used in a variety of settings, from manufacturing to assembly lines.

• Rigid Shaft Collars: Rigid collars are constructed from durable materials and designed for applications that demand a high degree of stability. Their strength makes them suitable for high-load scenarios, ensuring reliable performance in tough environments.

Selection Criteria for Shaft Collars in Industrial Settings

Choosing the right shaft collar involves considering several factors specific to your application. First, assess the environment where the collar will be used. Factors such as temperature, exposure to chemicals, and load requirements play a significant role in the selection process. For instance, environments with high humidity or corrosive substances may require collars made from materials resistant to such conditions.

We place a strong emphasis on the significance of matching the collar type to your operational requirements. Longevity and dependability are also guaranteed, in addition to peak performance. This personal touch ensures you find the best solution tailored to your unique requirements.

Installation ease and maintenance should also be part of your selection criteria. Some collars offer straightforward installation processes, while others may require specialised tools. Understanding these nuances can save time and resources in the long run, ensuring that your machinery operates smoothly without unnecessary downtime.

For nearly 30 years, Australian Pulley Co. has proudly manufactured Aluminium Vee Belt Pulleys and associated engineering components from diverse materials, including steel, cast iron, and nylon. Look through our range to discover how we can support your projects with reliable solutions that meet your needs.